PDS Series Photoresist Dispensing Pump

Repeatable accuracy of 0.3% of the discharge volume is maintained at all times.

-

- Repeated precision: ±0.3% (F.S.)

- Linearity: ±0.5% (F.S.)

- Resolution: 0.01 ml or below

For more information about applications relating to the PDS pump, please email customer service at info@iwakiamerica.com

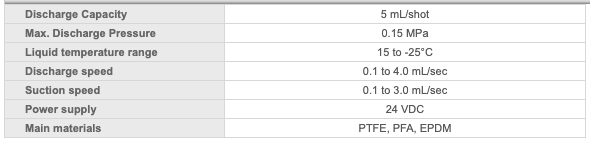

Max. Capacity: Up to 5 mL/shot

- Superior resist handling – The use of high-torque, stepper motor technology results in a consistent controllable discharge volume. The discharge volume is not affected by changes in viscosity or by filter performance.

- High Purity – The pump end utilizes a tubephragm design eliminating dead volume and low velocity areas where resist can stagnate. This prevents the collection of particles and allows the pumps to maintain the highest purity possible.

- Flexibility in Applications – The discharge velocity as well as volume are easily adjusted to expand the capabilities to many resist-coating processes, including the application of small amounts of resist in a short period of time.

Tubephragm Technology Explained

A tubephragm pump utilizes a hydraulically actuated flexible tubular diaphragm clamped at both ends. In operation, the plunger moves rearward and through hydraulic coupling expands the tube admitting liquid into the tube’s cavity through the suction check valve. As the plunger moves forward, the hydraulic fluid constricts the tube moving the process liquid through the discharge check valve. A disc diaphragm constrained by contour plates may be used in series hydraulically. This disc diaphragm is used to ensure that the tube operates within its elastic limits.

Videos