Application | Paper Mill

Iwaki America pumps are great for the transfer and addition of bleach to paper whitening process and the addition of amines and caustic to the process. One important application is the transfer and addition of bleach solutions. Bleaching agents, such as chlorine dioxide or hydrogen peroxide, are essential for achieving the desired level of brightness in paper production. Pumps enable the accurate dosing and controlled delivery of bleach solutions into the pulp or paper stock, ensuring uniform distribution and effective whitening of the fibers.

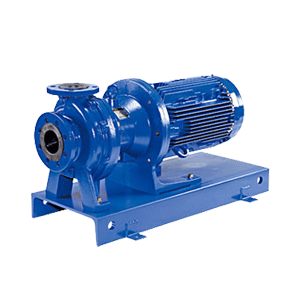

MDM Series

350 GPM / 350 ftMDM Series

Max. Capacity:

350 GPM

1400 LPM

Max. Head:

350 ft

107 m

MXM Series

160 GPM / 140 ftMXM Series

Max. Capacity:

160 GPM

600 LPM

Max. Head:

140 ft

42 m

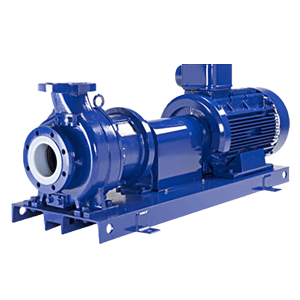

MDW Series

1320 GPM / 329 ftMDW Series

Max. Capacity:

1320 GPM

5000 LPM

Max. Head:

329 ft

98 m

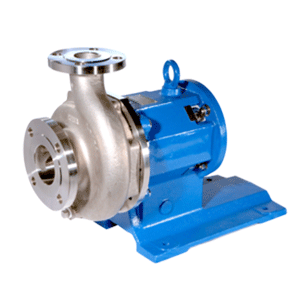

Metallic Series

340 GPM / 390 ftMP Series

Max. Capacity:

340 GPM

1290 LPM

Max. Head:

390 ft

118 m

MX(F) Series

225 GPM / 128 ftMX(F) Series

Max. Capacity:

225 GPM

852 LPM

Max. Head:

128 ft

39 m

SMX(F) Series

132 GPM / 119 ftSMX(F) Series

Max. Capacity:

132 GPM

Max. Head:

119 ft

36 m

MD/WMD Series

35.6 GPM / 66.6 ftMD/WMD Series

Max. Capacity:

35.6 GPM

135 LPM

Max. Head:

66.6 ft

20.3 m

Metallic Series

24 GPM / 92 ftMMP Series

Max. Capacity:

24 GPM

90 LPM

Max. Head:

92 ft

28 m

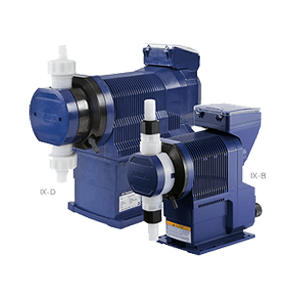

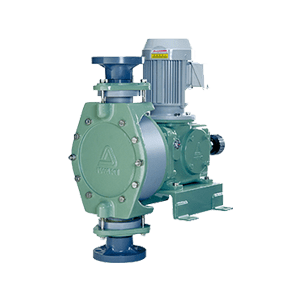

IX Series

80 GPH / 250 PSI / 140 SPMIX Series

Max. Capacity: 80 GPH

Max. Pressure: 250 PSI

Strokes per minute: 140 SPM

LK Series

856 GPH / 145 PSI / 116 SPMLK Series

Max. Capacity: 856 GPH

Max. Pressure: 145 PSI

Strokes per minute: 116 SPM

Pumps play a crucial role in precisely introducing amine solutions into the paper stock, promoting optimal fiber retention and overall paper quality. Similarly pumps are employed to accurately add caustic solutions, ensuring the desired pH level and facilitating necessary chemical reactions during the papermaking process. By utilizing pumps for the transfer and addition of bleach, amines and caustic chemicals, paper mills can achieve precise and controlled dosing, ensuring consistent quality throughout the paper whitening and production processes. Proper pump selection, maintenance and monitoring are critical to ensure reliable and efficient chemical transfer, leading to high-quality paper production.

Videos