Application | Bio Diesel Generators

Iwaki America pumps are great for the addition of Sulfuric and Caustic during the starch conversion or liquefaction stage. Pumps are essential for the addition of Sulfuric acid and Caustic during the starch conversion or liquefaction stage in bio-diesel generators. This stage involves the breakdown of starch present in biomass feedstocks to produce bio-diesel fuel. Sulfuric acid is used to hydrolyze the starch into simpler sugars, while Caustic (usually Sodium Hydroxide) is added to adjust the pH level during the reaction.

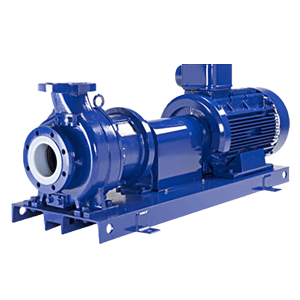

MDM Series

350 GPM / 350 ftMDM Series

Max. Capacity:

350 GPM

1400 LPM

Max. Head:

350 ft

107 m

MXM Series

160 GPM / 140 ftMXM Series

Max. Capacity:

160 GPM

600 LPM

Max. Head:

140 ft

42 m

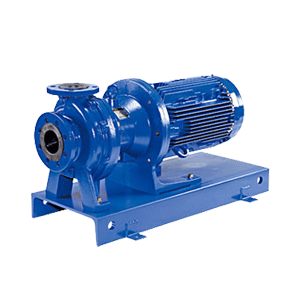

MDW Series

1320 GPM / 329 ftMDW Series

Max. Capacity:

1320 GPM

5000 LPM

Max. Head:

329 ft

98 m

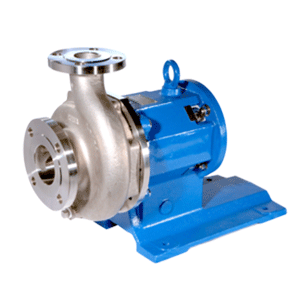

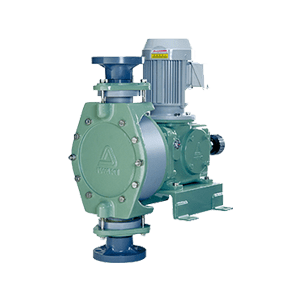

Metallic Series

340 GPM / 390 ftMP Series

Max. Capacity:

340 GPM

1290 LPM

Max. Head:

390 ft

118 m

MX(F) Series

225 GPM / 128 ftMX(F) Series

Max. Capacity:

225 GPM

852 LPM

Max. Head:

128 ft

39 m

SMX(F) Series

132 GPM / 119 ftSMX(F) Series

Max. Capacity:

132 GPM

Max. Head:

119 ft

36 m

MD/WMD Series

35.6 GPM / 66.6 ftMD/WMD Series

Max. Capacity:

35.6 GPM

135 LPM

Max. Head:

66.6 ft

20.3 m

Metallic Series

24 GPM / 92 ftMMP Series

Max. Capacity:

24 GPM

90 LPM

Max. Head:

92 ft

28 m

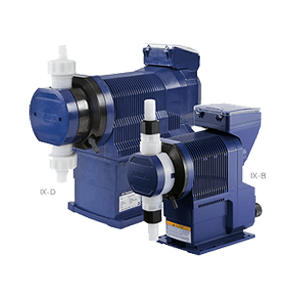

IX Series

80 GPH / 250 PSI / 140 SPMIX Series

Max. Capacity: 80 GPH

Max. Pressure: 250 PSI

Strokes per minute: 140 SPM

LK Series

856 GPH / 145 PSI / 116 SPMLK Series

Max. Capacity: 856 GPH

Max. Pressure: 145 PSI

Strokes per minute: 116 SPM

Pumps are responsible for accurately metering and delivering the required amounts of Sulfuric acid and Caustic into the bio-diesel production process. These pumps ensure precise dosing, maintaining the desired concentrations of the chemicals and facilitating efficient starch conversion. They also allow for precise control and adjustment of flow rates, ensuring optimal conditions for the reaction. Additionally, pumps used in this application are designed to handle the corrosive nature of Sulfuric acid and Caustic, with appropriate materials and safety features to ensure reliable and safe operation. By employing pumps for the addition of Sulfuric acid and Caustic, bio-diesel generators can effectively carry out the starch conversion or liquefaction stage, leading to the production of high-quality bio-diesel fuel.

Videos