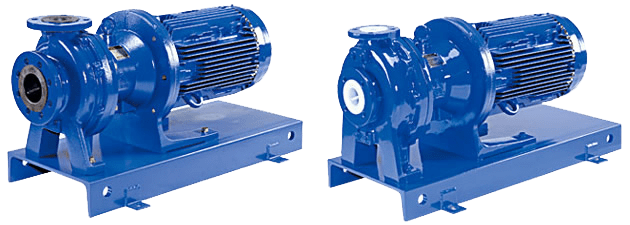

MDM Series

Iwaki’s MDM magnetic drive chemical process pumps are designed to solve the most demanding chemical handling applications. Two materials of construction and convenient mounting configurations allow MDM to handle many aggressive chemical and high purity applications. MDM pumps feature a unique non-contact system design that enable them to withstand dry running in comparison with conventional magnetic drive pumps made of fluororesin. MDM pumps are ideal for chemical transfer on chemistries such as bleach and sulphuric acid.

Now in stock!

Now in stock!

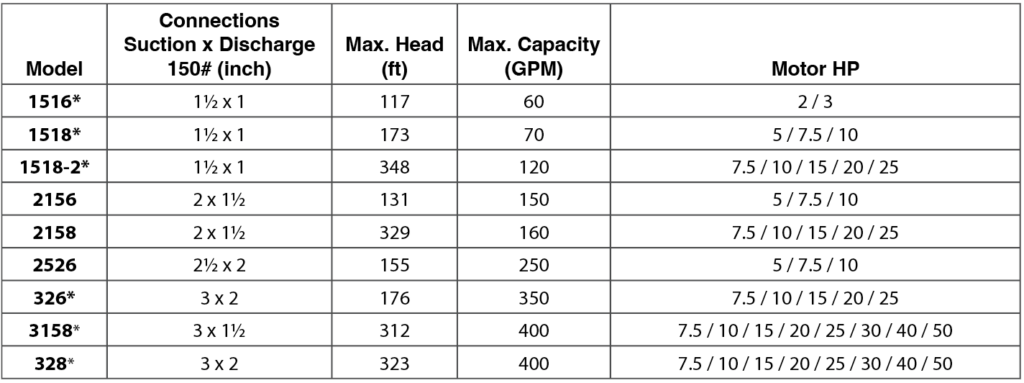

New 3 x 1.5 x 8″ and 3 x 2 x 8″ pumps

Max. Capacity: Up to 400 GPM

Max. Capacity: Up to 400 GPM

- Unexpected dry running won’t damage the pump or interrupt the process. Our dry run (carbon/ceramic) design allows the pump to handle these situations with ease.

- An expanded temperature range (up to 300°F) as well as increased solids handling capabilities (up to 10%) provides users with solutions for their difficult applications.

- Two materials of construction and convenient mounting configurations allow MDM to handle many aggressive chemical and high purity applications.

- Installation and maintenance time are reduced with our compact, close-coupled design.

- Operating costs are reduced thanks to simple, modular construction and individually replaceable parts.

- Small, lightweight and perfectly concentric magnet capsules optimize pump efficiency.

- High strength rare earth magnets are totally encapsulated within fluororesin moldings.

- MDM’s back pull-out design allows the operator to inspect the pump while leaving the line pressurized. MDM’s modular design keeps your operating cost low over the life of the pump by making regular maintenance and periodic inspection a snap.

* ANSI Dimensional Pump

- MDM-1516 (2HP)

- MDM-1516 (3HP)

- MDM-1518 (5HP)

- MDM-1518 (7.5-10HP)

- MDM-1518-2 (7.5-10HP)

- MDM-1518-2 (15-20HP)

- MDM-1518-2 (25HP)

- MDM-2156 (5HP)

- MDM-2156 (7.5-10HP)

- MDM-2158 (7.5-10HP)

- MDM-2158 (15-20HP)

- MDM-2158 (25HP)

- MDM-2526 (5HP)

- MDM-2526 (7.5-10HP)

- MDM-326 (7.5-25HP)

- MDM-3158 (7.5-50HP)

- MDM-328 (7.5-50HP)

- Chemical Manufacturing

- Metal Finishing

- Metal Pickling

- Mining

- Paper Mill

- Ethanol – Bulk Metering

- Chlorination Plants

- Refineries

Videos