Why Magnetic Propulsion is Key to Reliable and Durable Pumping Solutions

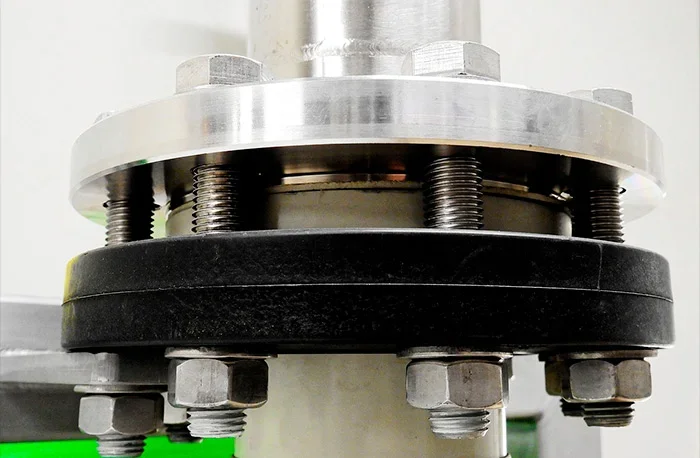

iwakiamerica-emarketing2025-03-11T09:45:08-04:00Industrial pumping processes require reliability and durability. Critical operations that depend on pumps require systems that can endure severe environments, reduce downtime, and be efficient. Amongst these technologies, magnetic propulsion has become a game-changer in developing reliable and durable pumping solutions. Specifically, Mag Drive pumps have been of much interest because they provide efficient, leak-free performance without the use of mechanical seals. Let's take a closer look at why magnetic propulsion is important for reliable and durable pumping solutions, focusing particularly on Mag Drive Centrifugal pumps and their advantages in industrial applications. Understanding Mag Drive Pumps Mag Drive pumps are a [...]

Videos