KBR Bellows Pump

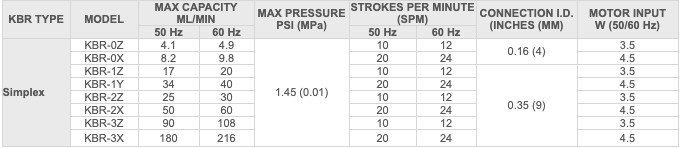

Several applications require precise and accurate dosing of fluids at low pressures. Addressing these specific requirements of equipment manufacturers, Iwaki America has developed a full line of economical, versatile, simplex and multiplex KBR bellows pumps featuring rugged gear-motor drives and flexible designs. Proven performers, Iwaki America bellows pumps are extensively used in photography, plating and electronics industries. Offered with optional DC motor options, these KBR bellows pumps can easily achieve a maximum capacity of up to 216mL/minute in challenging environments.

Max. Capacity: Up to 216 mL/min

- Blow-molded polypropylene bellows ensuring even wall thickness for long life

- Easy output adjustment, Simple liquid end construction assuring trouble-free pumping

- Anti-syphon spring (Hastelloy C) available

- Sure-seating elastomeric poppet valves provide positive backflow protection

- Optional duckbill valves for slurries

- Thermoplastic motor housing, Stainless steel or non-metallic frame

- DC motor options available

Maintenance Guidelines for Bellows Metering Pumps

Like any other industrial metering pumps, our bellows metering pumps require regular maintenance. The following tips will be helpful in this context.

- Inspect the pump for any wear and tear every time before operating it.

- Disassemble and inspect the pump carefully once a year.

- Switch off the power if you find any abnormality in the pump functioning.

Tips to Troubleshoot KBR Bellows Pumps

Although designed for industrial metering applications, KBR bellows pumps may not function as desired. You may notice any of the following symptoms:

- Liquid is not sucking in

- Liquid is not discharged properly

- Too small flow rate

- Liquid leaks

These symptoms may be due to the following reasons.

- Wrong mounting direction of valve: This can be a major reason for failed liquid suction and weak liquid discharge. Mount the valve in the correct direction to mitigate this issue.

- Foreign matters are stuck to the valve: If this happens, you may notice inappropriate liquid suction, insufficient liquid discharge, a small flow rate, and liquid leaks. To overcome these challenges, you must clean the valve periodically.

- Broken and damaged bellows: This can cause low/no flow and leakage; thus, it is always recommended to perform visual inspection before starting the bellows metering pumps. If you notice any damage to the bellows, then replace the part immediately.

- Loosened Cap: Can cause liquid leaks and insufficient suction. Hence, check and tighten the cap immediately.

- Air locked in the pump: This can hamper the suction or the working of the pump. If you notice this, remove the discharge side hose, fill the bellows with liquid and reconnect the hose.

- Air sucking through the suction port: This could be due to improper hose connections. Disconnect and reconnect the hose to ensure proper pump functioning.

- Dry running: This can be one of the reasons for insufficient metering, so you should fill the liquid in the tank before operating the pump again.

- Short stroke lengths: It can be easily mitigated by adjusting the stroke length. You need to operate the pump at 100% of its stroke length to make this adjustment.

Applications of KBR Bellows Metering Pumps

KBR bellows metering pumps are widely used in the following industries.

- Pharmaceutical and Biotechnology: In pharmaceutical and biotechnology industries, accurate fluid metering is important, and this requirement can be easily met using bellows pumps. We provide bellows metering pumps for applications such as bioreactor dosing, drug formulation, liquid chromatography, vaccine production, etc.

- Water and Wastewater Treatment: Our bellows pumps are widely used in the water and wastewater treatment industries for dosing chemicals for pH adjustment, disinfection, coagulation, and flocculation. These pumps help meet the regulatory requirements by ensuring the precise dosing of chemicals.

- Oil and Gas Industry: The bellows pumps are used in the oil and gas industry for chemical injection, corrosion inhibition, well stimulation, and flow assurance. Our bellows pumps can be operated in various challenging environments.

- Food and Beverage Industry: Precise dosing at low pressures is important in the food and beverage industry. This helps maintain consistency and quality. Our pumps have been used successfully for several years for dosing flavors, colors, additives and other chemicals during food and beverage processing.

- Pulp and Paper Manufacturing: These pumps are used in pulp and paper manufacturing industries for dosing chemicals during pH control, bleaching and coating applications.

Do you want to explore the possibilities of using these KBR bellows pumps for your dosing applications? Contact our team today to learn more about our KBR bellows pumps and analyze the possibilities of utilizing them in your applications.

Videos