FF / FF-H Series Pneumatic Drive Bellows Pump

Energy Saving Design

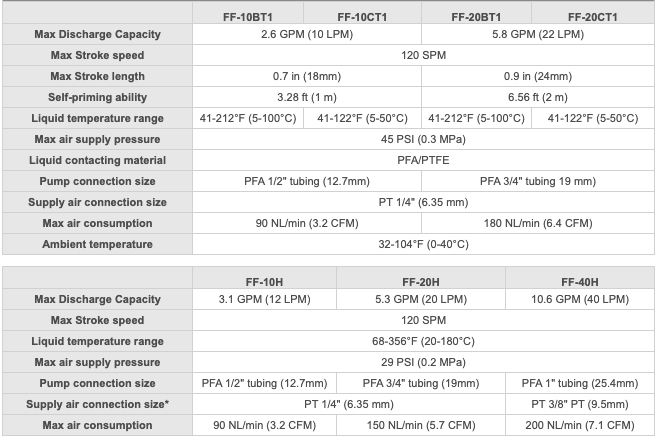

The FF series are specified for use with medium temperature liquids (The PVC cylinder type: 5 to 50˚C; Al cylinder type: 5 to 100˚C.) and the FF-H series are designed to handle a wide range of chemical liquids ranging from ordinary temperatures to high temperatures (20 to 180˚C).

Max. Capacity: Up to 11.6 GPM

- The FF-10/20CT1 has a PVC housing coated with fluoroplastic, suitable for liquids up to 50°C; a fluoroplastic encapsulated housing allows the FF-10/20BT1 to pump fluids up to 100°C.

- The liquid end parts are made entirely from fluororesin and free from contamination as they are designed so as to use neither rubber nor metal. As the bellows are completely welded with the body of the FF-H series, there is no leakage due to heat cycles.

- All liquid ends are constructed of fluoropolymers for purity and corrosion resistance. The PTFE bellows are rugged and proven to withstand long term continuous operation and high pressure resistance better than any other pump.

- Integral PFA tube connections mean there are no crevices or seams where particles can accumulate. A wide variety of fittings can be easily attached. Intelligent sensor technology is a standard FF series feature: pressure, stroke and speed are optimized, maintaining accurate chemical delivery and extending pump life. Leak detection ensures immediate response to hazards. Leak detection and drive sensing enhance the reliability and safety of these pneumatic pumps.

- High purity and exceptional performance are central to the design mission of the FF-H pumps. The PTFE bellows, PFA valves, and tubing are welded, ensuring the greatest possible resistance to contamination.

Videos