SMX(F) Series

Self Priming Magnetic Drive Pump for Efficient Fluid Transfer

Self-priming pumps are popular centrifugal pumps that can prime themselves automatically without any external assistance when manual priming becomes difficult. They are designed for applications where the fluid levels may vary or they may be forced to operate with a dry suction line. In both scenarios traditional centrifugal pumps cannot manually prime themselves. Iwaki America’s SMX series of magnetically driven non-metallic pumps offer an innovative true self-priming design with no mechanical seals that facilitate years of trouble-free service. SMX features a self-radiating bearing structure and non-contact dry-run capability enabling them to withstand the rigors of abnormal operating conditions across industries. The SMX series offers superior repeatable self-priming performance utilizing an integral priming and air separation chamber. SMX(F) magnetic drive pumps are ideal for chemical transfer on chemistries such as bleach and sulfuric acid.

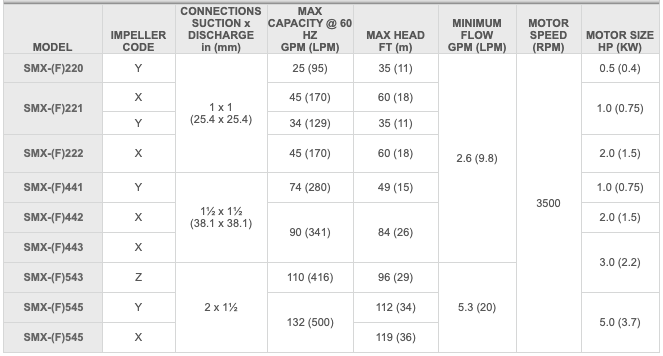

Max. Capacity: Up to 132 GPM

- Quick priming – Able to dry lift up to 13 feet in under 90 seconds.

- Expanded versatility – The SMX has a modular structure to handle liquids with high specific gravities. Use of standard motors extends the range of applications.

- Easy maintenance – The pump wet end can be removed from the motor as a complete assembly without dismantling, thanks to an additional rear casing support. The simple, rugged design with a minimum number of parts allows for easy maintenance.

- Enhanced durability under abnormal operation – Our original self-radiation structure (Patented) efficiently disperses bearing friction heat to protect the pump under abnormal operating conditions. In addition, our non-contact structure prevents contact between rear thrust face and bearing, to eliminate heat buildup during dry running.

- Motor options – SMX(F) series mounts to NEMA C-faced motors allowing for limitless voltage and service choices.

Factors of Consideration When Choosing Self-Priming Centrifugal Pumps for Your Application

There are several factors to consider when choosing self-priming water pumps to meet your pumping requirements. Here are some key considerations:

- Application requirements: Every pumping application is different; so, you need to address the application requirements to choose the right pump. When doing this you need to find answers for the questions such as how the pump will be used, the type of fluid to be pumped, chemical properties of the fluid such as their viscosity, abrasiveness, and corrosiveness, flow rates of the liquid, total pressure, and any special considerations unique to your application.

- Priming time: You must consider the priming time, which is the time taken to evacuate the suction pipe. The priming times differ with each pump. During the process of priming, vacuum is created when the fluid circulates in the casing. Needless to say, the priming time impacts the overall efficiency and the performance of the system.

- Fluctuating Fluid Levels: If the fluid is drawn from tanks, the tank levels may differ due to environmental conditions or usage. Care must be taken to choose the pump that can withstand differing flows at various heights without encountering challenges such as cavitation or too much suction pipe distance.

- Suction lift: This is the maximum vertical distance the pump requires to lift the fluid from the source. The self-priming pumps are designed for certain suction lift heights, thus, ensure the pump you choose can achieve the desired lift height. You can check the suction lift specifications offered by the manufacturer to make a decision.

- Solids handling: You may want to use the pump for pumping slurries or fluids with high solid content. In this scenario, ensure the self-priming pump can handle such materials. To ensure the same, you must focus on features such as large solids handling capabilities, built-in filters, non-clogging impellers, or strainers.

- Air handling capacity: Self-priming pumps can be used to handle different types of fluids including air, water, and gas. If you wish to pump air or gas in the fluid then focus on the specific handling capacities of the pumps. Some self-priming pumps may possess better air handling capabilities, which are ideal if your application involves fluids with entrained gases or a high air content.

- Efficiency and performance: Self-priming pumps are quite unlike other centrifugal pumps, and their efficiency is much lower compared to the former. You must review the pump’s power requirements, performance curves, and efficiency ratings to understand its operational characteristics..

- Construction materials: Self-priming centrifugal pumps feature multiple components made of different materials such as cast iron, stainless steel, bronze, cast steel, thermoplastics, Viton (FKM), nitrile rubber, ceramic, and so on. You must evaluate the compatibility of the pumping fluid with the construction materials. Consider factors such as chemical compatibility, corrosion resistance, and wear resistance to ensure long-term reliability and durability.

- Maintenance and serviceability: Although designed to perform in challenging work environments, these pumps may fail at times. Foreseeing the scenario, you must consider the factors like availability of spare parts for the chosen pump, support for repair and maintenance, and so on. Look for features like accessibility to internal components, replaceable wear parts, and manufacturer support to ensure smooth operation and minimize downtimes.

- Manufacturer support: When buying the pump, you must focus on factors like warranty, technical support, turnaround times for OEM parts, and availability of service centers to ensure ongoing support and assistance if needed.

Applications of Self-priming Centrifugal Pumps

Self-priming centrifugal pumps are used across industries and environments to pump different types of fluids including water, chemicals, air, and gas. The following are some popular applications of self-priming centrifugal pumps.

- Water Treatment: Self-priming water pumps are majorly used across rural water supplies, municipal water distribution, irrigation systems, and so on. They are used to lift water from different sources such as rivers, tanks, wells, and so on.

- Wastewater and Sewage Systems: These pumps are designed to handle liquids containing solids, which makes them an ideal choice for pumping sewage, sludge, effluent, and wastewater in commercial, industrial, and municipal settings.

- Construction and Dewatering: Self-priming centrifugal pumps are used in the construction industry for dewatering purposes. They are generally used for removing water from trenches, excavations, flooded areas, and so on.

- Marine and Offshore Applications: Self-priming centrifugal pumps are extensively used for a wide range of marine and offshore applications, such as fluid transfer on boats, ships, and offshore platforms, ballast water management, bilge pumping, and so on.

- Industrial Fluid Transfer: Our self-priming centrifugal pumps have been used for transferring a broad range of fluids, including chemicals, water, and petroleum products. They can withstand the rigors of these industries.

- Emergency Systems: Self-priming pumps are used for fluid transfer in flooded areas or areas hit with natural disasters to pump water and other petroleum-mixed fluids. They can be employed for critical operations like flood control, firefighting, and so on.

Do you want to know how self-priming pumps can be an asset to your facility? Contact our team today and we will be happy to answer all your inquiries about these pumps.

Videos