Metering Pumps

Iwaki offers a wide range of chemical metering pumps to satisfy a variety of chemical feed requirements. Iwaki strives to continuously design and manufacture high-quality chemical dosing pumps for diverse dosing applications across industries. The quality and performance of our precision metering pumps has been acknowledged for over 50 years. Mechanically-driven diaphragm metering pumps are available for general purpose applications; electromagnetic metering pumps with excellent controllability and accuracy fit smaller applications. Iwaki America’s chemical metering pumps are ideal for all of your chemical dosing applications. From micro-dosing to 856 gallons per hour, Iwaki America offers a broad range of chemical dosing pumps for your application.

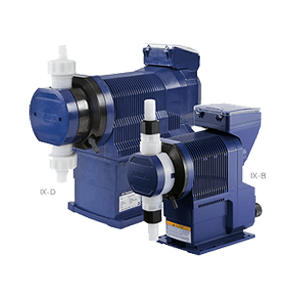

IX Series

80 GPH / 250 PSI / 140 SPMIX Series

Max. Capacity: 80 GPH

Max. Pressure: 250 PSI

Strokes per minute: 140 SPM

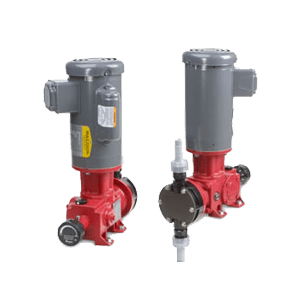

LKN Series

114 GPH / 225 PSI / 116 SPMLKN Series

Max. Capacity: 114 GPH

Max. Pressure: 225 PSI

Strokes per minute: 116 SPM

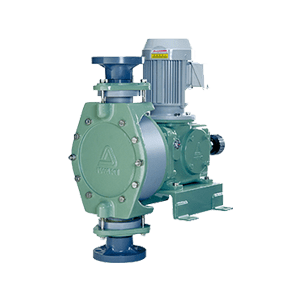

LK Series

856 GPH / 145 PSI / 116 SPMLK Series

Max. Capacity: 856 GPH

Max. Pressure: 145 PSI

Strokes per minute: 116 SPM

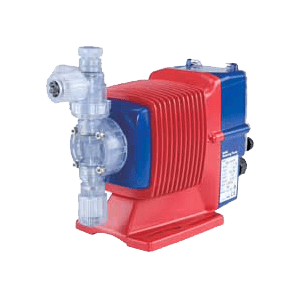

EJ Series

3.2 GPH / 175 PSI / 360 SPMEJ Series

Max. Capacity: 3.2 GPH

Max. Pressure: 175 PSI

Strokes per minute: 360 SPM

EZ Series

6.3 GPH / 150 PSI / 360 SPMEZ Series

Max. Capacity: 6.3 GPH

Max. Pressure: 150 PSI

Strokes per minute: 360 SPM

EHE Series

20.0 GPH / 150 PSI / 360 SPMEHE Series

Max. Capacity: 20.0 GPH

Max. Pressure: 150 PSI

Strokes per minute: 360 SPM

EWN Series

6.7 GPH / 290 PSI / 360 SPMEWN Series

Max. Capacity: 6.7 GPH

Max. Pressure: 290 PSI

Strokes per minute: 360 SPM

High Viscosity

4.0 GPH / 73 PSI / 240 SPMHigh Viscosity

Max. Capacity: 4.0 GPH

Max. Pressure: 73 PSI

Strokes per minute: 240 SPM

HRP Series

38 mL/min / 29 PSI / 720 SPMHRP Series

Max. Capacity: 38 mL/min

Max. Pressure: 29 PSI

Strokes per minute: 720 SPM

Types of Metering Pumps We Offer

Here are the types of chemical metering pump series we offer.

- IX Series: Can achieve a maximum capacity of 80 GPH and a pressure of 250 PSI. Suited for automated transfer and delivery of chemicals across industries.

- LKN Series: Can achieve a maximum capacity of 114 GPH (432 l/h) and a pressure of 225 PSI (1.5 MPa). Suited for chemical feed applications in agriculture and wastewater.

- LK Series: Can achieve a maximum capacity of 856 GPH (3240 l/h) and a maximum pressure of 220 PSI (1.5 MPa). Suited for large chemical feed applications across water treatment, agriculture, mining, and paper.

- EJ Series: Can achieve a maximum capacity of 3.2 GPH (12.0 LPH) and a maximum pressure of 175 PSI (1.2 MPa). Ensures providing high resolution chemical feed and high turndown capability.

- EZ Series: Can achieve a maximum capacity of 6.3 GPH and a maximum pressure of 150 PSI. Ideal for water treatment and OEM applications.

- EHE Series: Can achieve a maximum capacity of 20 GPH and a maximum pressure of 150 PSI. Performance of these chemical metering pumps combined with turndown ratio makes them the workhorse of the E-series metering pumps and makes them suited for a wide range of water treatment applications.

- EWN Series: Can achieve a maximum capacity of 6.7 GPH and a maximum pressure of 290 PSI. Possess high-speed dosing abilities.

- High Viscosity Pumps: Can achieve a maximum capacity of 4.0 GPH and a maximum pressure of 73 PSI. Suited for highly viscous fluids or chemicals.

- HRP Series: Can achieve a maximum capacity of 38 mL/min and maximum pressure of 29 PSI. Possess an adaptable modular design that makes them suitable for mounting in multiple locations.

Operational Mechanism of a Metering Pump

A metering pump, also known as a fluid metering pump, which is designed to accurately deliver precise amounts of liquid in industrial and chemical applications. The operational mechanism of a metering pump involves a few key components and principles:

- Pumping Mechanism: Metering pumps use a reciprocating or oscillating mechanism to displace and deliver liquid. This mechanism is often driven by a motor or an electromagnetic drive system. The reciprocating motion ensures accurate and controlled dosing.

- Pumping Chamber: The pumping chamber is where the liquid is contained and pressurized. It usually consists of a cylindrical chamber or a diaphragm. The chamber has an inlet and an outlet valve to control the flow of liquid.

- Inlet and Outlet Valves: The inlet and outlet valves regulate the flow of liquid into and out of the pumping chamber. These valves are typically check valves that allow the liquid to flow in one direction while preventing backflow.

- Control Mechanism: These chemical feed pumps incorporate a control mechanism to adjust the stroke length or frequency of the reciprocating motion, which determines the volume of liquid delivered per cycle. This control mechanism can be manual, mechanical, hydraulic, or electronic, depending on the type and sophistication of the pump.

- Adjustment and Monitoring: Chemical injection pump often have mechanisms for adjusting the stroke length, stroke speed, or flow rate to control the precise dosage. Some pumps may include sensors or feedback mechanisms to monitor and maintain the desired flow rate or pressure

- Priming and Pressure Relief: This solenoid metering pump may have priming mechanisms to remove air or gas from the pumping system. They may also incorporate pressure relief valves to protect the pump and the system from excessive pressure buildup.

Videos