Application | Plating

Plating and metal finishing requires many chemicals in the process. Iwaki America offers chemical transfer, recirculation and filtration pumps as well as replenishment pumps.

MDM Series

350 GPM / 350 ftMDM Series

Max. Capacity:

350 GPM

1400 LPM

Max. Head:

350 ft

107 m

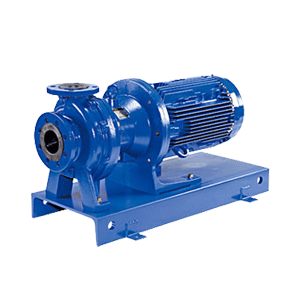

MXM Series

160 GPM / 140 ftMXM Series

Max. Capacity:

160 GPM

600 LPM

Max. Head:

140 ft

42 m

MDW Series

1320 GPM / 329 ftMDW Series

Max. Capacity:

1320 GPM

5000 LPM

Max. Head:

329 ft

98 m

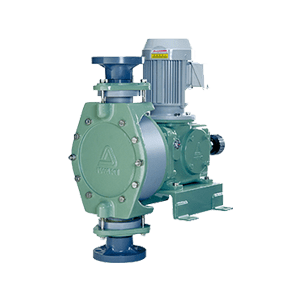

Metallic Series

340 GPM / 390 ftMP Series

Max. Capacity:

340 GPM

1290 LPM

Max. Head:

390 ft

118 m

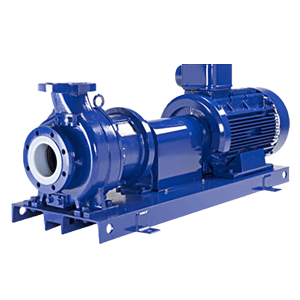

MX(F) Series

225 GPM / 128 ftMX(F) Series

Max. Capacity:

225 GPM

852 LPM

Max. Head:

128 ft

39 m

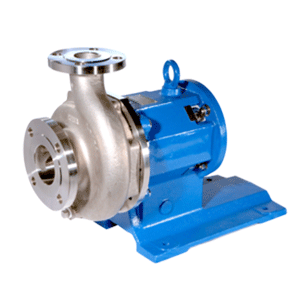

SMX(F) Series

132 GPM / 119 ftSMX(F) Series

Max. Capacity:

132 GPM

Max. Head:

119 ft

36 m

MD/WMD Series

35.6 GPM / 66.6 ftMD/WMD Series

Max. Capacity:

35.6 GPM

135 LPM

Max. Head:

66.6 ft

20.3 m

Metallic Series

24 GPM / 92 ftMMP Series

Max. Capacity:

24 GPM

90 LPM

Max. Head:

92 ft

28 m

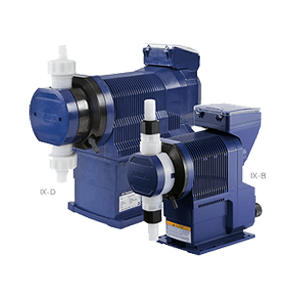

IX Series

80 GPH / 250 PSI / 140 SPMIX Series

Max. Capacity: 80 GPH

Max. Pressure: 250 PSI

Strokes per minute: 140 SPM

LK Series

856 GPH / 145 PSI / 116 SPMLK Series

Max. Capacity: 856 GPH

Max. Pressure: 145 PSI

Strokes per minute: 116 SPM

These pumps are essential components for the plating and metal finishing process. They are used for chemical transfer, recirculation, filtration, agitation and electrolysis. These pumps help maintain a consistent chemical balance and temperature, ensure the quality of the plating and filter out impurities from plating solutions and rinse water. By using chemical transfer pumps, the plating and metal finishing process can be more efficient and produce higher quality plating results. These pumps are responsible for maintaining the chemical balance and controlling the pH of the plating baths. They are also used to inject chemicals into waste treatment systems to neutralize & treat chemicals used in the plating process before disposal.

Videos