Hicera Series

Hicera V Series

Valveless Piston Metering PumpsHicera V Series

Max. Capacity

Up to 1682 L/min

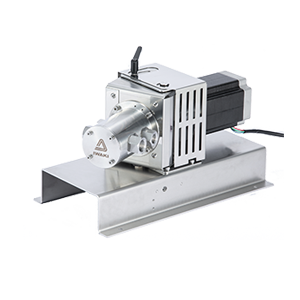

V-25 Series

Precision Valveless Plunger PumpV-25 Series

Max. Flow:

Up to 11 mL/shot

Reciprocating Diaphragm Technology Explained

In a typical electric driven diaphragm design the diaphragm is clamped in the pump head assembly and is actuated by an electric motor driving an eccentric cam connected to the diaphragm via a connecting rod. In addition to housing the diaphragm, the pump head also contains suction and discharge valves. As the cam rotates the diaphragm is pulled down via the connecting rod and a vacuum is created. The suction valve opens to allow the air/liquid into the expanding pump chamber while the discharge valve is closed.

As the cam continues its rotation, the diaphragm is pushed up and the pump chamber volume is reduced pushing the air/liquid out through the discharge valve while the suction valve is closed. During a complete stroke the diaphragm moves up and down creating the suction and discharge cycle. This up and down movement creates a vacuum on the suction stroke and positive pressure on the discharge stroke. Diaphragm pumps are also self-priming. To handle the significant difference in physical properties between liquids and gases, specific diaphragm designs and valve configurations have been developed. Those suited to handling gases only may not offer the best solution for liquid applications and this should be taken into consideration during application review and system design.

Iwaki America’s APN-W series pumps are specifically designed to handle liquids as well as gas/air/liquid mixtures, making them ideal for tough applications where all situations are present.

Videos