Magnetic Drive Pumps

Magnetic drive pumps by Iwaki America are the cornerstone of our OEM pump solutions. These pumps use no shaft seal, instead the impeller is rotated via a magnetic coupling. With over 60 years of experience in the design, application and manufacturing of magnet drive pumps, we have built a worldwide reputation for superior quality and reliability. Our mag drive OEM pumps feature hollow rotating spindle, unmatched hydraulics and premium efficient motors. All these properties ensure performance, quality, reliability, and the best value of investment that you expect from your OEM pumps.

MD/WMD Series

36 GPM / 135 LPMMD/WMD Series

Max. Capacity:

36 GPM /135 LPM

Max. Head:

39.9 ft / 11.0 m

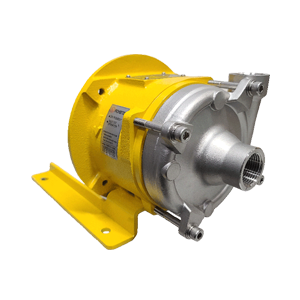

MX(F) Series

130 GPM / 492 LPMMX(F) Series

Max. Capacity:

130 GPM / 492 LPM

MDG Series

Up to 1.7 LPMMDG Series

Max. Capacity:

Up to 1.7 LPM

MDT Series

Up to 20 LPMMDT Series

Max. Capacity:

Up to 20 LPM

MA/MB Series

Up to 22 GPMMA/MB Series

Max. Capacity:

Up to 22 GPM/(5.81)

Sanwa M Series

Sanwa M Series

Tips to Choose the Right Magnetic Drive OEM Pump for Your Application

Our extensive collection of magnetic drive OEM pumps comprises MD/WMD Series, MX (F) Series, MDG Series, MDT Series, and MA/MB Series. These pumps differ in flow rates, pumping capacities, temperatures, etc. This diversity may make the selection challenging. The following pointers will help in an easy selection.

- Pump Bearings: Our WMD & MD pumps feature alumina ceramic bearing materials and a polypropylenebody, suited for regular media. However, if you plan to use aggressive media or wish to use the pump to transfer the media with high purity requirements, choose pump bearings made of optional SiC (silicon carbide) and an ETFE (fluoropolymer) body.

- High Operating Temperatures: The magnetic drive OEM pumps feature magnets inside them, which could demagnetize at high temperatures. Hence, to avoid this, you must choose a pump that can be operated at the proper temperature range. Additionally, the users must take care to dry run the pump, because it can harm the pump’s bearing system. Our mag drive OEM pumps are designed for high-temperature applications. They can handle solutions rated up to 280 degrees Celsius.

- Dry Running: In many scenarios, the pumps may dry run or the suction side valves may be closed, which would damage the pump interiors. If dry running is a possibility, then MX Series should be considered. This is because magnetic drive OEM pumps from this series can tolerate brief intermittent dry running operations for up to 1 hour. The pumps with the “CF” bearing system identifier in the model number are specifically designed for dry running.

How to Optimize the Value of Your Mag Drive OEM Pump Investments

You can optimize the value of your mag drive OEM pumps by following the below-given handling instructions.

- Do not allow the pump to run dry.

- Turn off the power before starting the pump.

- Prime to fill the pump cavity with liquid.

- Release the trapped air in the pump drive shaft by manually rotating it. If this is not done, your pump bearing system will damage.

- Next, close the discharge side valves, turn on the power, and start the pump.

- When stopping the pump, close the discharge side valve gradually. When it closes completely, then switch off the power and the pump will stop.

- Do not operate the pump beyond its maximum pressure rating.

- Avoid using the pump for handling slurries of higher concentration.

- Choose the pump in the required specific gravity and specific temperature range.

Are you looking for magnetic drive OEM pumps for your challenging fluid transfer applications? Get in touch with us today. You can call us at 508.429.1440 or mail us at info@iwakiamerica.com to learn more about our magnetic drive pumps.

Videos