Magnetic Drive Pumps

Iwaki America’s large and small/medium magnetic drive chemical pumps assure safe fluid transfer and long service lives. Our magnetic drive pumps are designed for industries that are regulated by the strictest safety protocols and environmental regulations. Our 60+ years of experience are a testament to our high quality and advanced design.

Large Mag Drive/Chemical Process Pumps

Iwaki America offers a full range of large magnetic drive pumps up to 100 HP. Our large mag drive pumps portfolio features the MDM Series, MXM Series, MDW Series, and Metallic Series. These mag drive pumps can produce a total dynamic head 390 ft. (98m). They can be used to pump acids, caustics, and low- or high-temperature fluids in various process applications. Browse our selection to find a large mag drive pump for your needs!

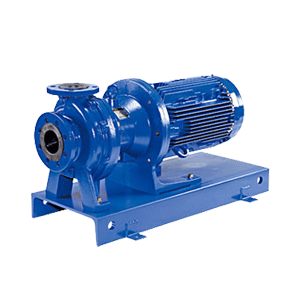

MDM Series

400 GPM / 350 ftMDM Series

Max. Capacity:

400 GPM

1514 LPM

Max. Head:

350 ft

107 m

MXM Series

160 GPM / 140 ftMXM Series

Max. Capacity:

160 GPM

600 LPM

Max. Head:

140 ft

42 m

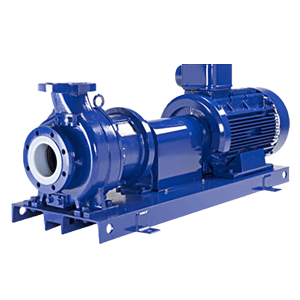

MDW Series

1320 GPM / 329 ftMDW Series

Max. Capacity:

1320 GPM

5000 LPM

Max. Head:

329 ft

98 m

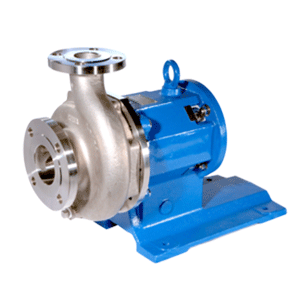

Metallic Series

340 GPM / 390 ftMP Series

Max. Capacity:

340 GPM

1290 LPM

Max. Head:

390 ft

118 m

Applications of Large Magnetic Drive Pumps

- Metal Finishing

- Chemical Manufacturing

- Metal Pickling

- Mining

- Ethanol – Bulk Metering

- Paper Mill

- Chlorination Plants

- Chemical Toting and Packaging

- Refineries

Small/Medium Mag Drive Chemical Process Pumps

Iwaki America provides a wide range of small/medium magnetic drive pumps from 1/250th to 5 HP. Our portfolio of small/medium mag drive chemical process pumps comprises MX (F) Series, SMX (F) Series, MD/WMD Series, and Metallic Series, with the highest total dynamic head of 128 ft. (20.3m). These magnetic drive chemical pumps can withstand the rigors of the process industry and are ideal for the chemical transfer of such chemicals as sulfuric acid and bleach.

MX(F) Series

225 GPM / 128 ftMX(F) Series

Max. Capacity:

225 GPM

852 LPM

Max. Head:

128 ft

39 m

SMX(F) Series

132 GPM / 119 ftSMX(F) Series

Max. Capacity:

132 GPM

Max. Head:

119 ft

36 m

MD/WMD Series

35.6 GPM / 66.6 ftMD/WMD Series

Max. Capacity:

35.6 GPM

135 LPM

Max. Head:

66.6 ft

20.3 m

Metallic Series

24 GPM / 92 ftMMP Series

Max. Capacity:

24 GPM

90 LPM

Max. Head:

92 ft

28 m

NRD Series

18.5 GPM / 62.3 ftNRD Series

Max. Capacity:

18.5 GPM

Max. Head:

62.3 ft

Working Principles of Magnetic Drive Pumps

Magnetic drive pumps, also known as magnetically coupled pumps, operate based on the principle of magnetic force. These plastic chemical pumps are commonly used in various industries, including the handling of corrosive or hazardous fluids where leakage prevention is crucial.

The working principle of magnetic drive pumps involves the use of a magnetic coupling that connects the driving motor and the impeller. The coupling consists of two magnets, an outer magnet connected to the motor shaft and an inner magnet attached to the impeller. These magnets are separated by a sealed containment shell, typically made of non-magnetic materials such as plastic or ceramics.

When the motor shaft rotates, the magnetic field created by the outer magnet induces a corresponding magnetic field in the inner magnet, resulting in the rotation of the impeller. The magnetic forces transmitted through the containment shell allow the transfer of torque from the motor to the impeller without any physical connection.

The absence of a direct shaft connection eliminates the need for traditional shaft seals, which are prone to wear and leakage over time. This design feature makes mag drive pumps highly reliable and ideal for handling corrosive or toxic fluids, as it effectively prevents leakage and ensures the safety of the environment and personnel.

Magnetic Drive Sealless Pumps In Hydrochloric Acid Processing

Magnetic drive sealless pumps are the ideal choice for hydrochloric acid pumping applications. These hydrochloric acid pumps offer exceptional resistance to corrosion and eliminate the risk of leaks by removing mechanical seals. With their durable construction using corrosion-resistant materials, they ensure longevity and reliability in the presence of hydrochloric acid. The magnetic drive sealless technology enhances safety by minimizing the chances of spills or leaks. These pumps possess excellent chemical resistance, making them well-suited for hydrochloric acid pumping applications without degradation or damage. Their sealless design reduces maintenance requirements and associated downtime, enabling continuous and efficient operation. Investing in magnetic drive sealless pumps for hydrochloric acid processing results in cost savings by reducing the need for frequent pump replacements. Operators can rely on these pumps to handle hydrochloric acid safely and effectively, ensuring smooth and reliable operations.

Applications of Small/Medium Magnetic Drive Pumps

- Water Treatment

- Chemical Blending

- Bio-Diesel Generators

- Fume Scrubbers

- Kidney Dialysis

- Plating

- Bio-Fuels

- Precision Cleaning Systems

- Sodium Hypochlorite Generators

- Desalination

Videos