MX(F) Series

The MX Series pumps of magnetic drive pumps represent the latest state of the art design in non-metallic magnetic drive pumps. With the experience gained from previous generations of MDH pumps, the MX Series has been engineered to meet the most severe operating conditions. MX(F) magnetic drive pumps are ideal for chemical transfer on chemistries such as bleach and sulphuric acid.

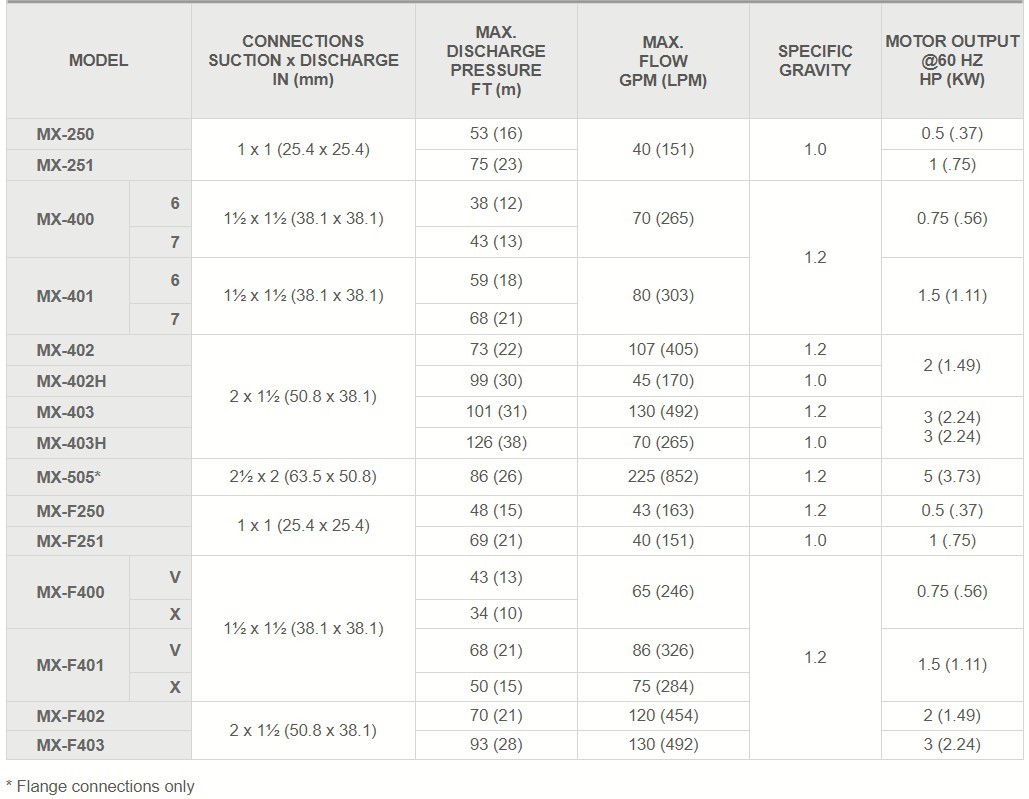

Max. Capacity: Up to 225 GPM

- Self-radiating structure – When fitted with a carbon bearing, the MX will allow for brief periods of dry running. The new “self radiating structure” (patented), in addition to the existing proven non-contact principle with front and rear supported spindle, greatly improves the ability to withstand cavitation and running against a closed discharge valve.

- Split volute casing – The MX Series is the first resin magnet pump that uses a split volute pump casing that forms a vortex chamber. The volute limits the liquid flow from the impeller and returns it to the pump, which is efficiently guided to the discharge port to enhance overall efficiency.

- MX Series pumps are highly recommended for use in various production processes such as filtering, spraying, washing, plating, chemical transfer/blending, and etching in surface treatment applications.

- MX utilizes standard NEMA frame motors making them easy to install. (IEC and JIS versions available)

- Non-metallic baseplate will not corrode in hostile environments.

Polypropylene

ETFE (Teflon®)

Polypropylene

ETFE (Teflon®)

- Chemical Blending

- Water Treatment

- Plating

- Sodium Hypochlorite Generators

- Bio-Fuels

- Desalination

- Fume Scrubbers

Videos